Sustainability

How do you do more with less? That’s the ultimate sustainability challenge.

Innovation

In a changing world, you need a partner that is comfortable when the rules change.

Our solutions

Superior products and services supported

by our global team of foundry experts.

Foseco blog

Achieve more with our advice, tips and resources for the modern foundry.

18 Dec 2024

Thermo-physical data for the FOSECO feeder sleeve and filtration product ranges are integrated and made available in ESI’s ProCAST (& QuikCAST) software.

03 Jun 2024

Discover the critical role of advanced coatings such as HARDCOTE SF800 in eliminating common casting defects such as sand inclusions and metal penetration.

10 May 2024

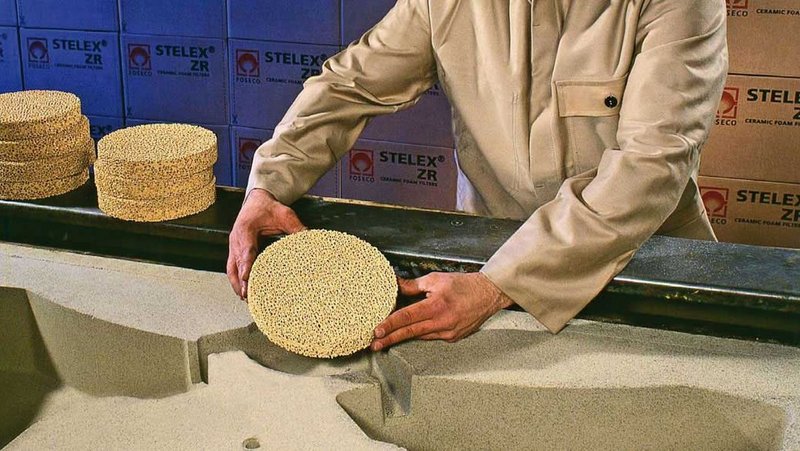

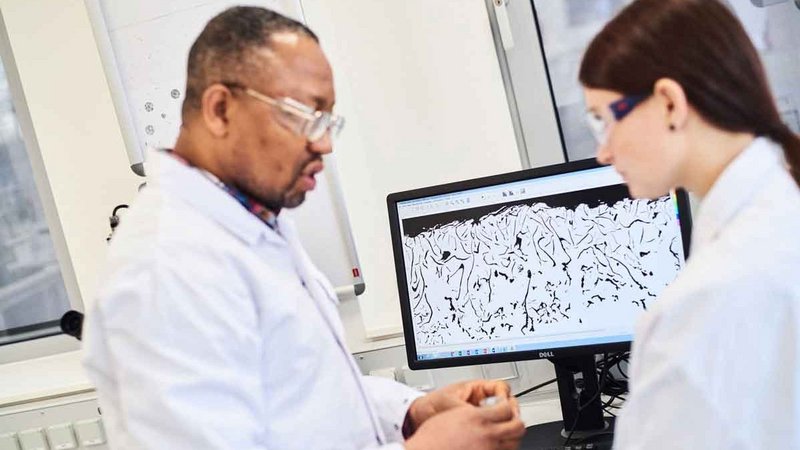

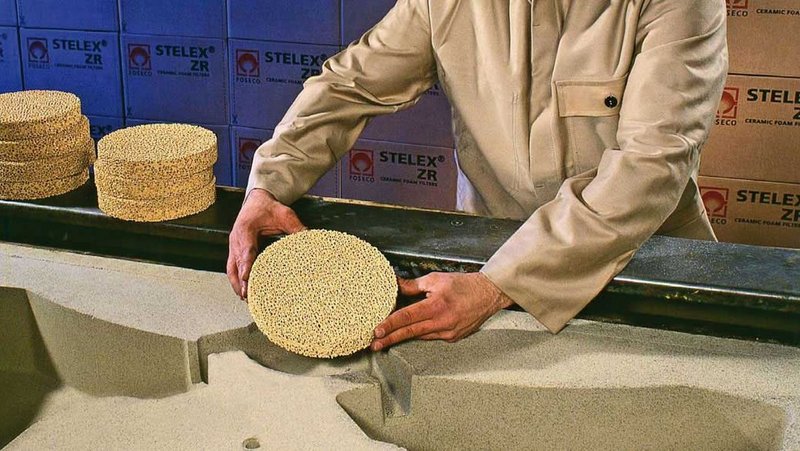

Filtration cuts inclusion defects—but many foundries still don’t use it. With new advances in filter performance, that’s starting to change.

02 Apr 2024

Non-metallic inclusions are the top cause of casting defects—but they’re not all the same. This article explores the most common types in ductile iron, steel, and aluminium, and how to prevent them.

Coating for green sand moulds

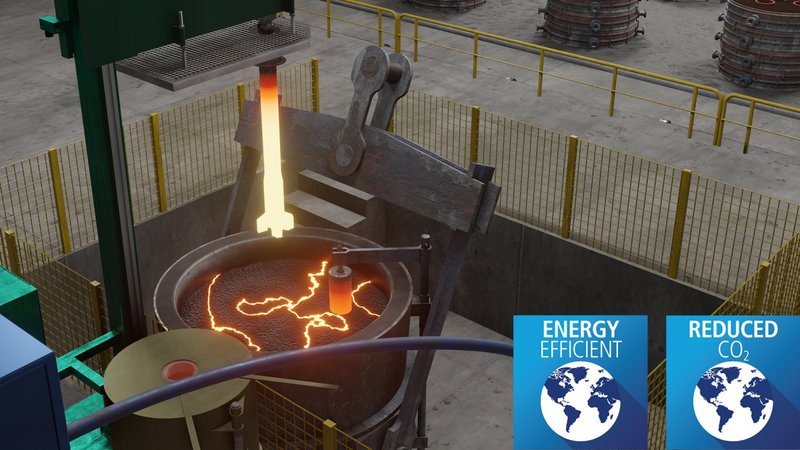

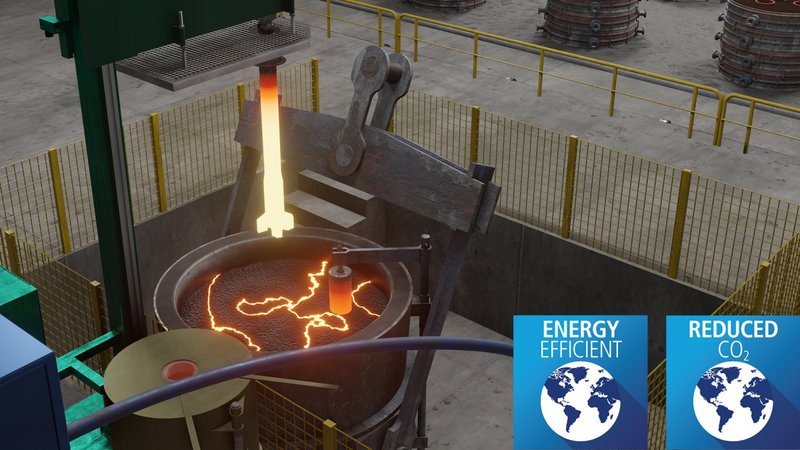

Innovatiove process for the rotary treatment of molten metal in the pouring ladle

Coatings to improve economic, social, and environmental sustainability at foundries

Fluoride emission free, highly exothermic and high pressure-resistant feeder sleeve

28 Jun 2023

Foseco joins forces with the WFO at GIFA 2023, spotlighting a unified approach to foundry sustainability and innovation for a thriving future.

26 Jun 2023

Foseco received the ecoMetals ecoProcess Award at GIFA 2023 for its SEMCO range of water-based coatings—recognised for saving energy, materials, and resources in foundry operations.

25 Jun 2023

Sustainability was a key theme at GIFA 2023—but what does it mean for foundries? Alexander Laugier-Werth, VP Sustainability at Vesuvius, shared his insights at the event.

24 Jun 2023

Since 1932, Foseco has delivered more than products—it's delivered solutions. At GIFA 2023, VP Rob Welland confirmed that commitment still drives the company today.

Services

Wherever you are in the world, expert advice is always just a phone call away. Our technical specialists will be delighted to provide application advice, conduct process audits and deliver training that’s designed to maximise the benefits our solutions create.

Innovation

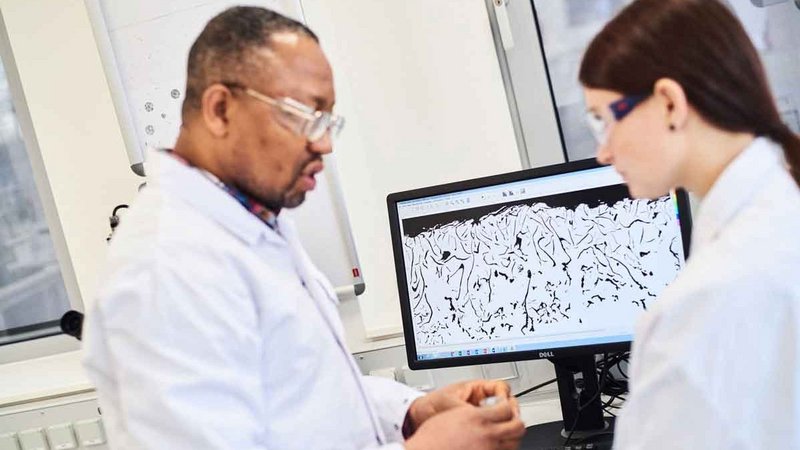

All Foseco products are born from the need to find better ways of producing better castings more efficiently and economically, and are the result of close collaboration with foundry operators the world over. Our approach is built on close personal relationships where it matters most - on the foundry floor.

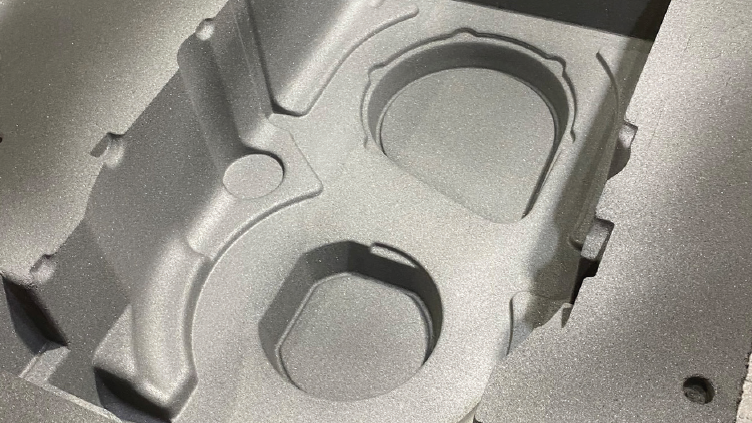

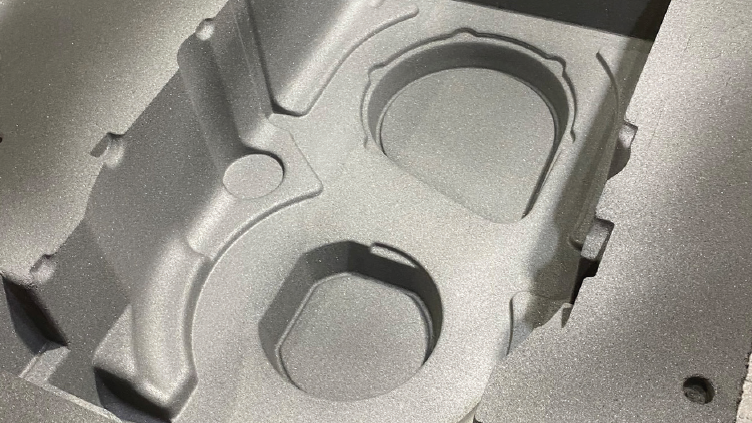

The causes of casting defects are numerous and can be found at most stages of the casting process - from the furnace to the mould. Casting defects significantly affect the efficiency, profitability and environmental performance of foundries. Our solutions and advanced computer simulation techniques allow foundries to reduce casting defects such as pinholes, shrinkage cavity, inclusions, scabbing, penetration or veining. Hence the Foseco products reduce labour-intensive fettling and machining, minimise metal usage requirements, influence the metal solidification process and automate moulding and casting, thus reducing cost, energy usage and mould size.

Our aim is to enable improved foundry performance by working alongside our customers to develop and apply products and services that produce better casting quality and higher productivity at lower costs in a safe and healthy working environment.