Speciality coatings

Coatings for moulds and cores produced by additive manufacturing

TENO PRINT is a range of refractory coatings designed to overcome the limitations of moulds and cores produced by additive manufacturing (3D printing), including lower sand compaction and surface finish. To address these issues, the TENO PRINT range:

- Provides excellent surface coverage, smoothing out the step-like surface inherent to 3D-printed cores and moulds, and so ensuring casting surfaces are smooth and free from discontinuities

- Improves the interface between the molten metal and the sand surface, preventing metal penetration and sand burn-on defects associated with lower sand compaction.

The range of TENO PRINT coatings support varied application methods, with rheological properties adapted for both dipping and flow coat applications. The selection of refractory filler combinations is also optimised to casting application. Finally, TENO PRINT is an insulating coating that provides better control of solidification at lower castings weights, while maintaining excellent surface finish, free of common defects. It thus allows foundries to improve the metallurgical properties of current castings, while also developing designs that minimise casting wall thickness to further reduce total weight – improving yield and reducing energy consumption

Full mould and lost foam processes

The SEMCO perm and STYROMOL ranges of water based coatings are designed to promote excellent surface finish and dimensional stability of the polystyrene pattern. Permeability and composition have been specifically designed to meet the requirements of lost foam.

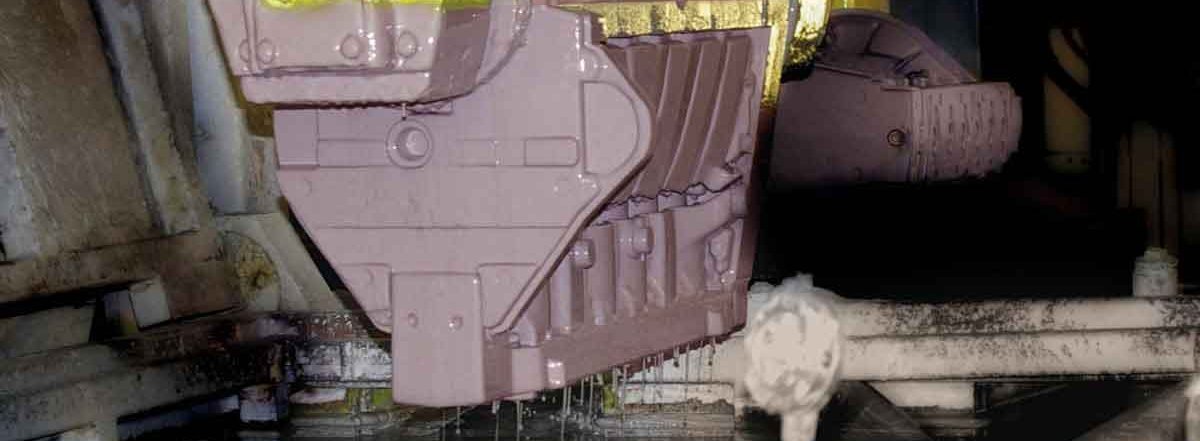

Spun pipe and rolls

SPUNCOTE coatings are products formulated to provide a permeable coating with very low gas evolution for the centrifugal casting process. The coating will help to deliver a smooth surface finish of the casting and promote easier stripping of the finished casting.

SPUNCOTE SP coatings are specially formulated to provide a range of textured surface to the centrifugally cast component especially suited to the production of cylinder liners, through the use of the appropriate coating and process parameters the texture can be defined as rough, spiny or wormy.

Metallurgical coatings

TELLURIT and MOLCO 50 are chill-promoting coatings are suitable for grey cast iron and are ideal for producing a wear resistant surface. In addition, there are several coatings in our SEMCO and TENO product ranges designed to help prevent flake reversion defects, especially those associated with acid set chemically bonded binder systems.

Coatings for tools and refractories

FRACTON coatings are used for the protection of refractory surfaces, metal dies and launders, pig moulds and other metal tools.

FRACTON 110BN is a boron nitride containing water based, fully thixotropic dressing and is ideally suited for the coating of refractory launder systems used to transfer molten aluminium.

CERAMOL 258G/2 is a water based coating containing zirconium silicate that minimises the adherence of metal and slag to crucibles and ladles, thereby increasing refractory life and ensuring a clean receptacle for the molten metal.