History

In 1931, Eric Weiss, then a young man of 22 decided to come to England. He had, from the age of 16, worked for his uncle, who mixed and sold fluxes for the improvement of castings in foundries. He had acquired much of the know-how which was the essential part of that service. He had no capital other than his knowledge and character. In England he borrowed £250 as working capital to start the business. With each man drawing £3 per week to live on, he and two others built up business connections. In the first year the profits amounted to £80. In 1934 he was joined in England by his friend, Kossy Strauss, whose knowledge of chemistry played a fundamental part in the growth of the enterprise. By 1949, Foseco was exporting to over 25 countries and the first local Foseco operations were established in France and North America, to be followed by a global network across the industrialised world.

1916

The Vesuvius crucible company is founded in Pittsbugh, USA by by Francis L. Arensberg, Charles F. Covert Arensberg and Arthur J. Jackman, with financial assistance of Edith Arensberg.

1932

In Birmingham, UK in 1932, Eric Weiss and Dr Kossy Strauss set up Foundry Services Ltd – the company that would become Foseco. Dr Strauss was a chemist, and with Eric Weiss on the commercial side, their mission was to provide products and services that truly supported the foundry industry.

From the very beginning, the company adopted a product plus technical service approach and published the first edition of Foundry Practice – a technical journal for foundries which is still going strong to this day.

1942

Foseco publishes the first Foundryman’s Handbook, a practical reference book for all those concerned with making castings in any of the commonly used alloys, by any of the usual moulding methods. Today it is available in its 11th edition.

1948

Foseco initiated the use of feeding aids with the development of FEEDEX powder, an exothermic heat source to reduce iron returns and cleaning costs, and FERRUX anti-piping covers are developed by Foseco.

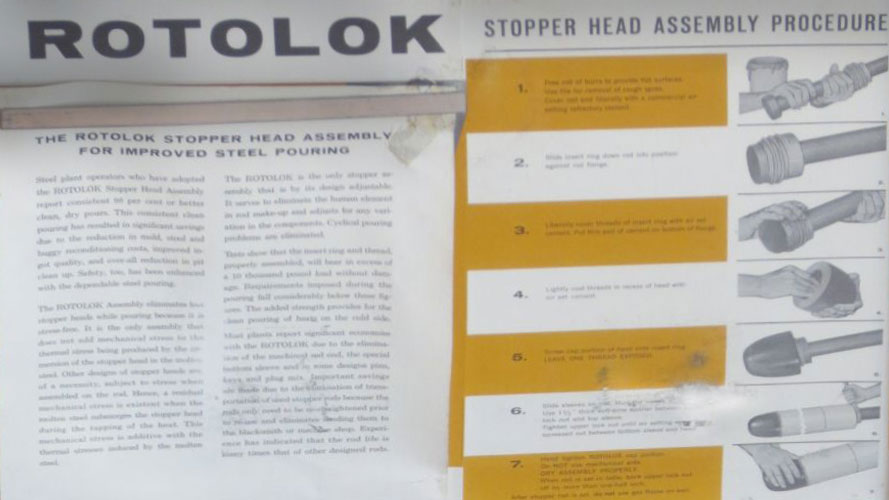

1958

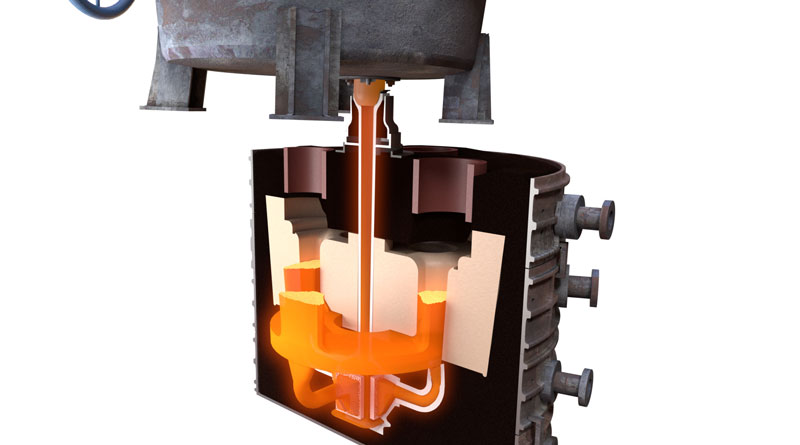

Vesuvius invents ROTOLOK, a pioneering product to control the flow of molten steel.

1960

Foseco develops the exothermic sleeve FEEDEX.

1964

The first R&D centre is built by Vesuvius in Pittsburgh, USA.

1982

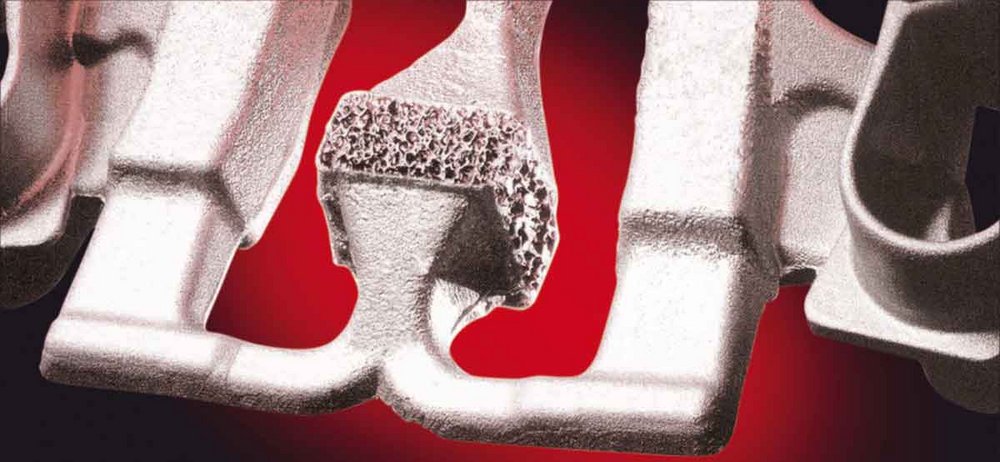

Foseco develops the SEDEX filter, a pioneering product in iron filtration.

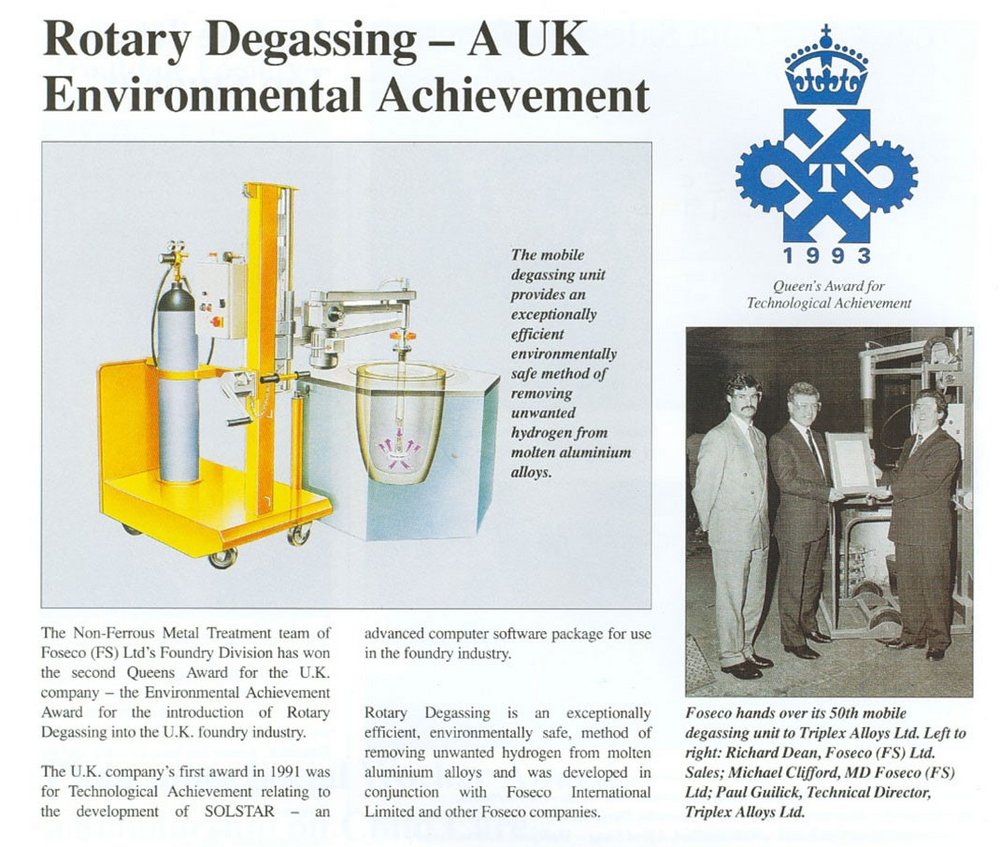

1993

Queens award for technological achievement for the development of the Foundry Degassing Unit, the first automated degassing system for aluminium foundries.

1996

Foseco develops STELEX ZR filters for steel filtration.

1999

Launch of SIVEX FC non ceramic foam filters for aluminium casting.

2003

RHEOTEC XL water based anti-veining coatings for demanding iron applications are introduced.

STELEX PrO carbon bonded filters launched opening up the application of filters to a broader range or iron and steel casting applications.

2007

Launch of FEEDEX K collapsible breaker core technology for the optimization of spot feeding.

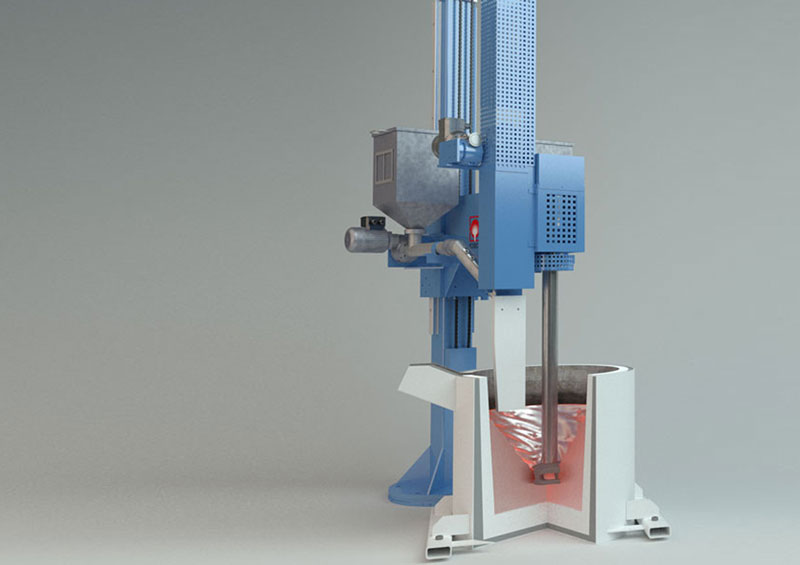

Development of the patented XSR rotor for optimum aluminium degassing performance.

2008

Foseco is acquired by Cookson plc and merges with Vesuvius. The two largest worldwide ceramic specialists for molten metal handling become one.

2009

ENERTEK energy efficient crucibles with optimised thermal performance save money and reduce carbon footprint.

2012

Vesuvius plc becomes a separately listed company as a result of the division of Cookson Group plc's businesses into two companies through a demerger.

2014

The global Foundry R&D centre is established in Enschede, Netherlands.

2016

Vesuvius celebrates 100 years of innovation.

2017

Launch of SMARTT Degassing for aluminium melts – an intelligent automated degassing and melt treatment process that adjusts treatment parameters in real-time based on ambient conditions, melt temperature, rotor design and alloy composition.

2018

Foseco’s fully automated Intelligent Coating Unit controls coating density in real-time and therefore delivers greater consistency in wet layer thickness.

Launch of SCK modular feeding systems to optimize feeding for larger iron and steel castings.

Foseco’s patented FEEDEX VAK spot feeder technology is the latest advance in the spot feeding of iron castibngs.

2019

Launch of FEEDEX NF1 feeder sleeves – the first exothermic sleeves designed specifically for aluminium castings.

Launch of SEMCO IC “Inner Cleanliness” coatings specifically developed to help automotive foundries to deliver the increasing quality demands specified for the next generations of emission-reduced and performance-enhanced internal combustion engines.

Lainch of the HOLLOTEX Shroud system offering advanced turbulence control and inclusion removal for large steel castings.

2020

Vesuvius launched the formal Sustainability strategy to bring together all our environmental, social and governance initiatives into one coordinated program. We developed a new governance structure to support our objectives and a new set of targets to direct our efforts. The strategy was built on four pillars: our planet, our customers, our people and our communities.

Foseco‘s latest range of DYCOTE SAFEGUARD die-coatings increase die operating life by up to 3 times compared to conventional coatings. This new range of die coatings have been developed specifically to maximise the service life and maintain surface quality for critical aluminium components such as aluminium wheels and cylinder heads.

SEMCO FD – fast dry waterbased coatings optimize productivity and save energy.

2021

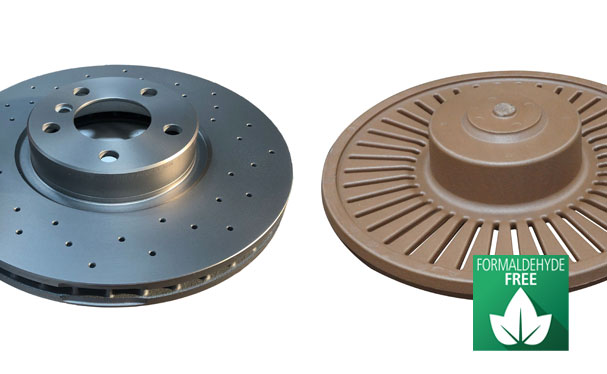

SEMCO FF water based coatings are launched. Designed to reduce evolved formaldehyde emissions, these coatings improve the working environment and support foundries’ compliance with the latest environmental regulations.

Foseco introduces FEEDEX FEF - a new fluoride emission free, highly exothermic high-strength feeder sleeve material for iron castings, especially suited to high-pressure automatic moulding lines.

2022

VESUVIUS PLC (GROUP) has been awarded a Gold medal as a recognition of their EcoVadis Rating

2023

Foseco won the prestigious ecoProcess Award in the ecoMetals category at GIFA 2023. The award specifically recognises Foseco's innovative SEMCO range of water-based coatings, highlighting their significant role in conserving energy, materials and resources within foundry operations.