Research & development

Customer focused. Solution driven. Service based. Our R&D thinks beyond today’s casting processes to shape the future of the foundry.

The world has changed a lot in recent decades. New challenges have arisen, as have new opportunities. What has not changed is the essential role castings play in the modern world. But to keep meeting the needs of foundries and casting end-users, we will have to think and work in new ways.

This means thinking beyond what we have done in the past, and what we are today. Beyond preconceived ideas of how to do things, and what our customers and casting users need. Although we respect the traditions and lessons of the past, if we and our customers are to continue to operate in and shape the foundry world, we must continuously work toward the foundry of the future.

This means two things. Firstly, it places central importance on the role of R&D. And secondly, it means collaboration – with our customers, with casting users, and with the wider industry. After all, innovation is only useful when it is firmly centred on the challenges that face the industry, whether that is sustainability, digitalisation and process control, quality improvement, productivity enhancement – or something as yet unforeseen!

When developing new products and process improvements, we therefore work closely with customers to ensure that our efforts are solution-driven, with customer needs placed front and centre of our thinking. Indeed, many of our key developments are a direct result of close collaboration with key customers. It is this ethos of service and support that drives our R&D efforts and ensures that we deliver advanced technologies that make tangible improvements to customer productivity and competitiveness.

Likewise, we always welcome customer input and direction on our R&D efforts. We thrive when a customer sets us a challenge and then works with us to discover the solution!

Do you have a problem to solve? Our R&D team is here to help.

A global R&D effort

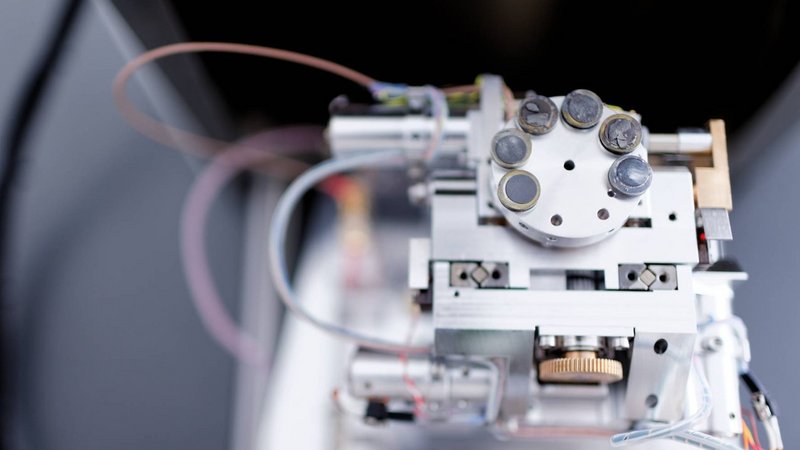

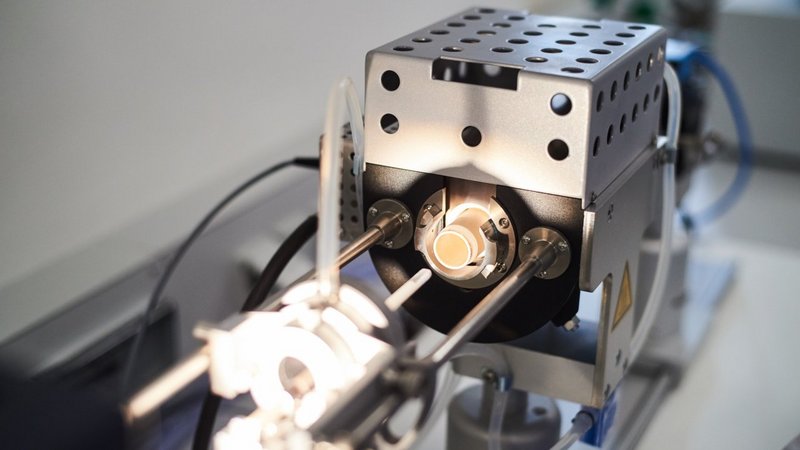

Our R&D centres draw on a diverse team of experts, who come from all over the world and from a variety of disciplines. Chemists, materials scientists, metallurgists, and mechanical engineers all work together to engineer new answers to new (and old) problems. Our R&D centres are also located close to, but distinct from, our production facilities. This ensures a close link is maintained between R&D and its practical implementation, while protecting the freedom to innovate.

We are proud of this team, but we are always looking to strengthen and expand our skills and expertise. So if you think you’ve got what it takes and are interested in shaping the future of the foundry and steel industries, we’re always interested in hearing from you.

Leading foundry R&D

At Foseco and our parent company, Vesuvius, we have a strong tradition of leading foundry R&D efforts. These cover a wide range of activities – from fundamental research, such as the evaluation of new materials and technologies, to product and process development, and the support of our production facilities.

Our original R&D centre was based in Pittsburgh, USA, the home of the US steel industry and where Vesuvius was born. We opened the Enschede R&D centre in the Netherlands in 2014 to focus specifically on innovation. We like to think of these centres as idea factories that manufacture solutions.

To support this process, our centres are equipped with the latest testing facilities, including:

- Microscopy

- Chemical analysis

- Physical properties

Meanwhile, our test foundry enables us to evaluate and perfect new ideas in-house, before taking them out to customer facilities.

Our capabilities

- Scanning electron microscope (SEM), surface examination

- Energy dispersive X-Ray analysis (EDX), chemical identification

- Optical microscopy

- 3D microscopy

- Induced coupled plasma – optical emission spectroscopy (ICP-OES)

- X-ray fluorescence (XRF)

- Combustion analyzer – detect carbon, sulfur, hydrogen, oxygen, nitrogen in metals, ores and minerals

- X-ray diffraction (XRD)

- UV spectrometer

- Aluminium analyser

- Florine analysis

- Simultanous themogravimetric analysis, coupled with mass spectroscopy (STA-MS)

- Heating microscope

- Dilatometer

- Particle size analysis

- Surface area analysis (BET)

- Pycnometer

- Optical tensiometer

- Mercury porosity and pore profile analyser

- Rheometer

- Instron for fracture testing

- High temperature (~ 1480°C) fracture testing

- Thermal shock (thermite testing)

Where to find our R&D centres

Global Foundry and Steel R&D Centre, USA

Vesuvius Research USA

4604 Campbells Run Road

Pittsburgh,

PA 15205

Global Foundry R&D Centre, Netherlands

Enschede Foundry R&D Centre

Pantheon 30

7521 PR Enschede

The Netherlands

Global Steel R&D Centre, Belgium

Fundamental Research VISO Global Research Systems Mechatronics COE

Rue de Douvrain,17

7011 Ghlin

Belgium

Global Steel R&D Centre, China

Asia Development FC Raw Material Opt

221 Xing Ming Street

China-Singapore Suzhou Industrial Park

Suzhou, China

Global Steel R&D Centre, India

India Development

Block E, Vadlapudi, Fakirtakya, 32, 1st Cross Rd,

Kurmannapalem, Visakhapatnam,

Andhra Pradesh 530046, India

Global Steel R&D Centre, Poland

EMEA Development

Tyniecka 12,

32-050 Skawina,

Poland

Enschede R&D centre facts

Highly qualified

Team

State of the art

Equipment

Lab space

600 sq

Employees

40

Pilot foundry

800 sq

Divers and

International

Pittsburgh R&D centre facts

Highly qualified

Team

State of the Art

Equipment

Lab Space

1860 sq

Employees

65

Office Space

1114 sq

Diverse and

International