Equipment for ferrous metal treatment

MSI in-stream inoculation systems

MSI represents a range of in-stream inoculant dispensing systems from Foseco. MSI systems are designed specifically for use with Foseco’s range of INOCULIN alloys. MSI systems can be customised to meet the unique needs of foundries and can be integrated with most automated pouring systems to achieve the highest level of metallurgical process control across a full spectrum of iron grades.

The system has an in-built computer and an RS232 interface and remote maintenance and control software is supplied as standard. The system monitors the inoculant level, discharge pipe, inoculant flow, sliding gate, compressed air and equipment temperature in real-time.

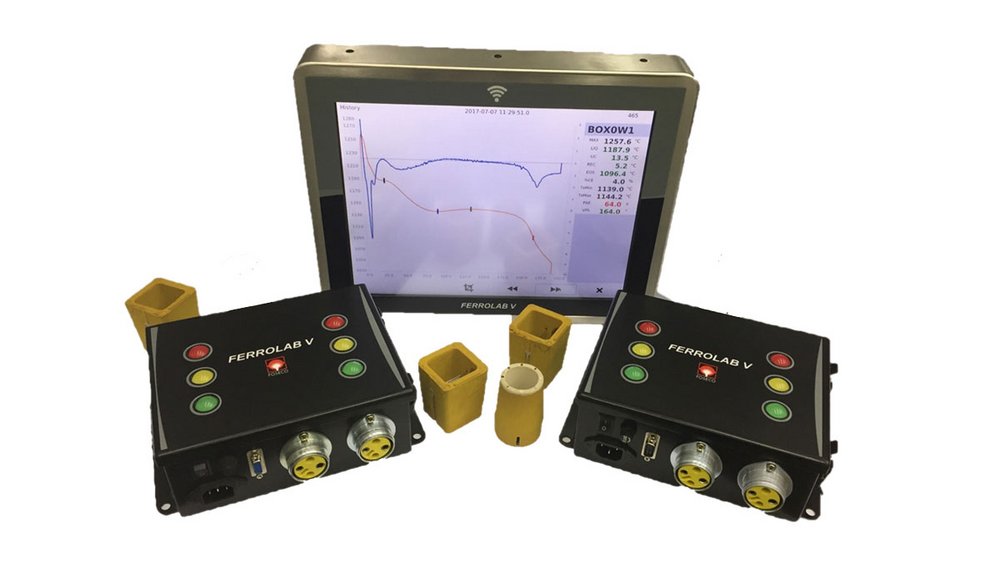

FERROLAB V advanced thermal analysis system

The FERROLAB V measurement system is a sophisticated thermal analysis tool that leads to uniform iron quality, less variation in the properties of castings and ultimately allows a reduction in the amount of castings rejected.

Full Ironmaking Coverage

- The Measurement System FERROLAB V is a perfect guide to reach optimal inoculant and nodulant additions;

- Usage in the melt deck is key to reach right physical properties of the base iron, to control nucleation, phase formation and shrinkage;

- Provides accurate monitoring and correction of possible changes in charge materials;

- Usage in the pouring station confirms physical properties and generates a quality record for each cast.

The system is provided free of charge to Foseco customers that buy our inoculants, nodularisers and sampling cups. And we work together with them to ensure that they can consistently produce the highest quality iron possible.

Continuous temperature measurement systems

ACCUMETRIX is an industrial temperature measurement system. The ACCUMETRIX system continuously monitors temperature in real-time inside the pour box of auto-pour and pressure pour furnaces.

The ACCUMETRIX system provides many operational benefits

- A continous, real-time temperature control measurement

- Improved operational flexibility through the display of temperature trends

- The elimination of manual temperature measurement providing improved operator safety

- Lower overall operating costs from the prevention of temperature-related breakouts and early warning of freeze-off