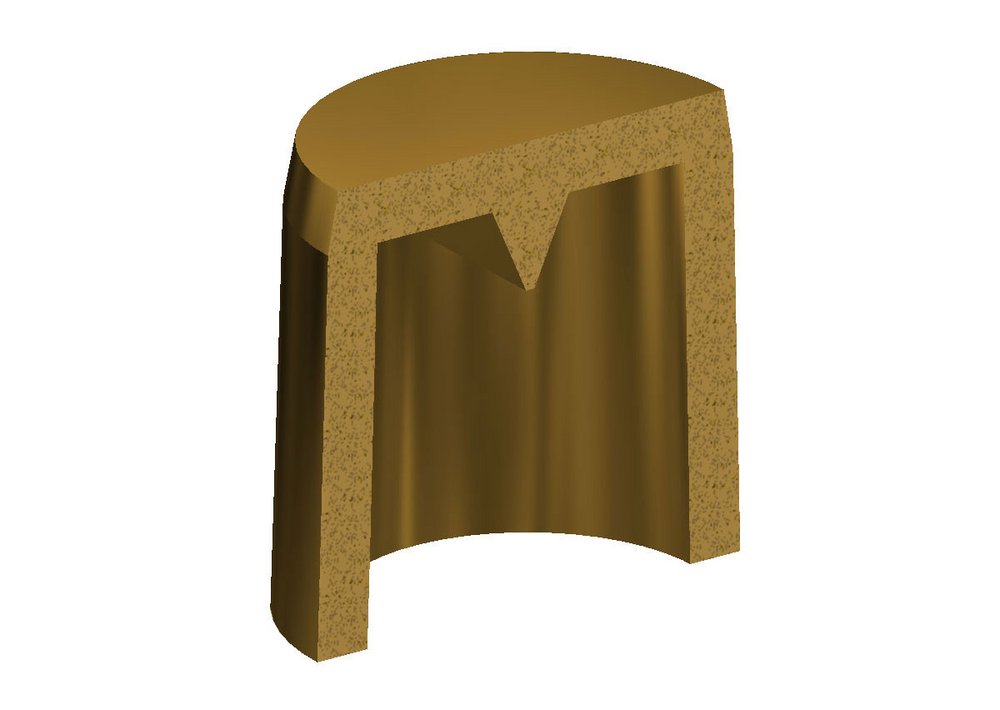

Insulating feeder sleeves

- Highly resistant to dilation

- Superior insulating characteristics

- Low smoke and fume emissions

- Increased casting yield

KALMIN insulating feeder sleeves for ferrous and non ferrous alloys

Insulating feeder sleeves are especially suited to applications where exothermic reactions create metallurgical problems, gas defects and other reaction problems.

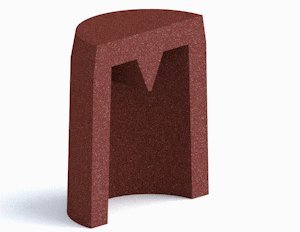

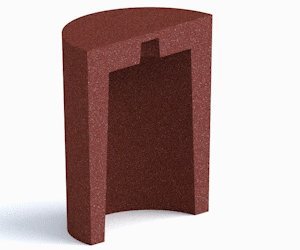

KALMIN S sleeves are a range of accurately formed, higher strength open and closed insulating feeders with a density of 0.45g/cm³. They are particularly suited to automated moulding lines and can be used in iron and smaller steel castings. They are also ideal for “floating sleeve” application.

Compared to sand feeders, KALMIN S sleeves show a 2 to 2.2 times extension in solidification time. Good insulating properties and the neutral behaviour of the sleeve material with both molten metal and moulding sand means that KALMIN S sleeves are suitable for a wide range of alloys.

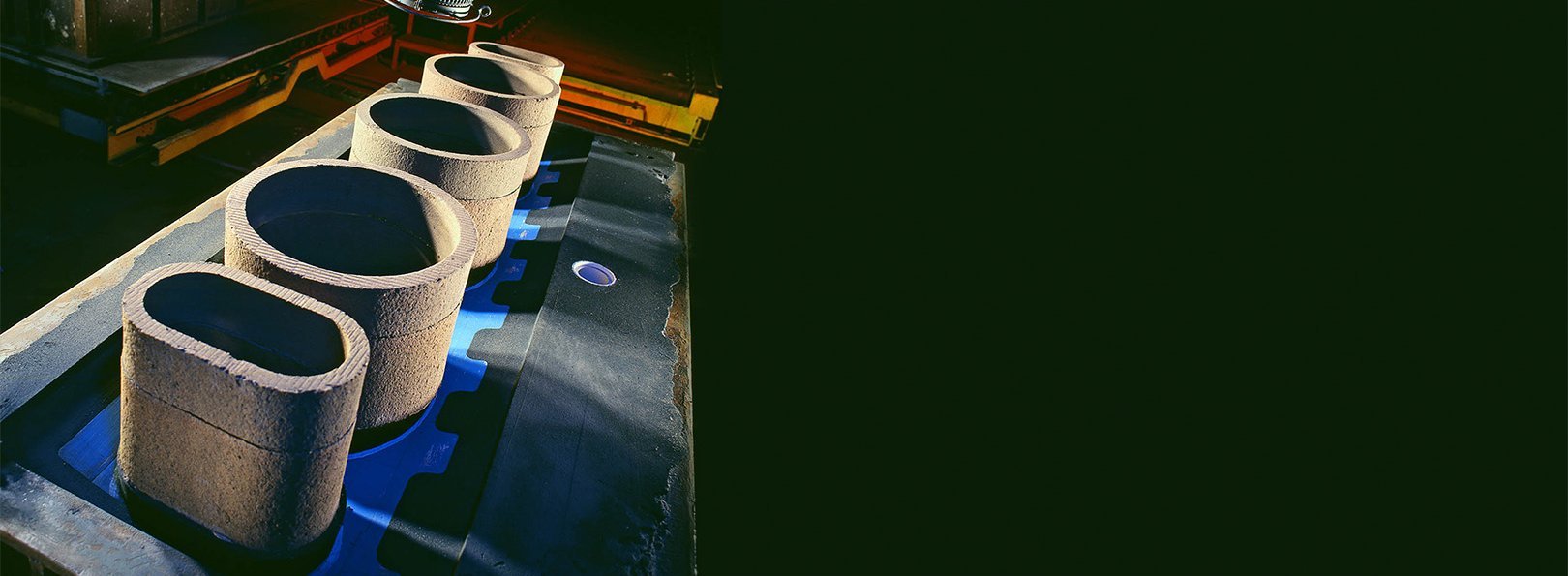

KALMIN 70 feeder sleeves are a range of highly refractory cylindrical oval feeder sleeves that have been specially developed for high-temperature insulation. Due to their high permeability and their purely insulating effect, KALMIN 70 feeder sleeves minimize potential problems caused by gas reactions during casting.

KALMIN 70 is and ideally suited to copper applications especially those with heavy sections and to all ferrous casting alloys and are especially recommended for high-alloyed steel grades.

KALMIN 250NE is a highly refractory feeding material available in a variety of shapes. They are free from organic materials and fume free during casting.

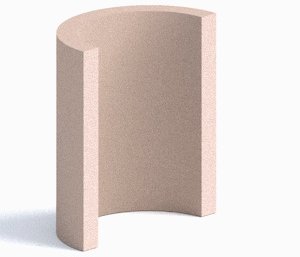

KALMIN 50A is a range of open cylinders and ovals for use in aluminium applications. Sleeves can be cut to fit the contours of the casting, or to the desired feeder height.