Exothermic-insulating feeder sleeves

- The exothermic reaction and high insulation factor ensure that feeder volumes are minimised, substantially improving yield

- Fettling costs are substantially reduced, especially where breaker cores are used

- Isolated sections can be adequately fed, reducing the need for expensive padding

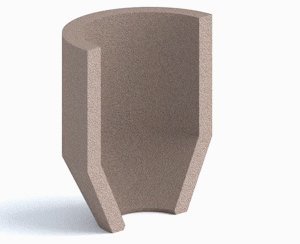

KALMINEX is an exothermic-insulating range of feeder sleeves supplied as preformed cylinders, ovals and neck-downs in a range of diameters up to 850 mm. They are ideally suited for jobbing iron and steel applications.

KALMINEX 2000 are accurately formed, highly exothermic and insulating shapes suitable for feeding all grades of cast iron and steel as well as copper. They are available as open or blind sleeves in the diameter range of 35-120 mm. Ideally applied as an insert sleeve, the high strength of KALMINEX 2000 means that they can also easily be used for ram-up applications.

KALMINEX SD are exothermic-insulating insert sleeves suitable for high pressure moulding equipment. KALMINEX SD sleeves attain 2 to 2.5 times the

pressure resistance of the similar design and size KALMINEX 2000 insert sleeves.

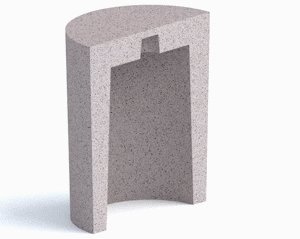

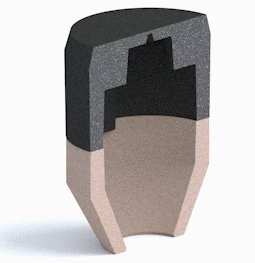

FEEDEX SCK - Sleeve Construction Kit

The SCK system is a modular system for jobbing iron and steel castings, allowing the foundry to tailor the sleeve package to the appropriate modulus to maximise yield and minimise the riser footprint.

The SCK set can be assembled to achieve the required modulus with smallest contact area. The system is therefore an ideal solution for casting sections which offer minimum footprints.

Excellent feeding efficiency will ensure a clean casting surface at the contact sleeve area. The highly exothermic components will be placed on the lower insulating parts via an interlock system. Locator pins are used for centering the set

Key benefits

- Components can be tailored to the required modulus and volume

- Lower inventory required to cover the variety of shapes needed

- Smallest possible contact surface and lowest penetration

- Minimisation of cleaning costs

- Good compressibility in the feeder neck

FEEDEX NF1 exothermic feeder sleeves for non ferrous applications

With the use of FEEDEX NF1 exothermic feeders, the use of exothermic powders can be avoided. The sleeve ignites within 20 seconds of coming into contact with melt and the steady and long-lasting exothermic reaction significantly delays solidification of the metal in the sleeve, ensuring excellent feed performance.

Key Benefits

- High exothermicity with improved feeding performance

- Very high strength

- Minimised fettling costs when used in combination with breaker cores

- Easy and quick knock-off of the sleeve and riser stub

- Reduced process variation

- Lower emissions