Sustainability has always been at the heart of our business. Our technology has helped our customers improve their processes and their environmental footprint.

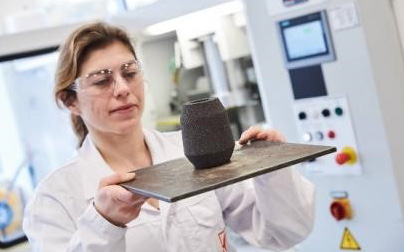

Fluoride emission free, highly exothermic and high pressure-resistant feeder sleeve

Christof Volks, European Product Manager Feeding Systems, comments:

“With the launch of FEEDEX FEF sleeve material, Foseco is proud to offer a highly sustainable and strongly performing feeder sleeve formulation. Importantly, we also realize another major step forward in our commitment to setting the benchmark for sustainability in the foundry industry. Our target is to become the first supplier to offer fully fluoride emission free feeder sleeves across our entire feeding product portfolio. We’re very close to achieving this goal.”

Christof Volks,

European Product Manager Feeding Systems