Supporting our customers’ journey to net zero

With sustainability becoming a strategic concern for many of our customers, we are focusing on developing products and services that help them improve their environmental performance and create a safer workplace. A set of icons highlighting the sustainability benefits of our products.

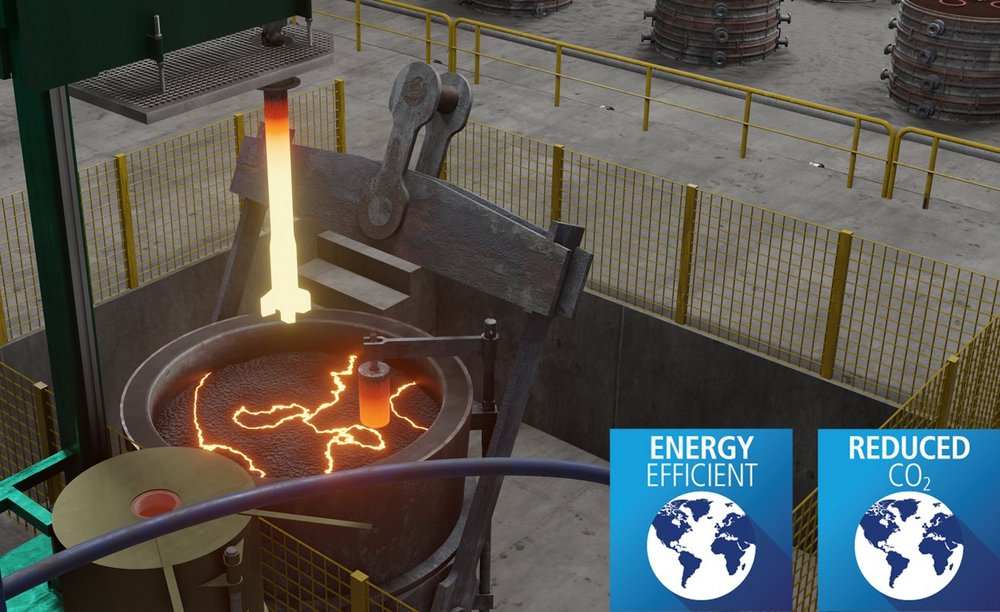

ROTOCLENE process

ROTOCLENE is a new process for producing the highest quality, inclusion-free steel for casting. The process uses rotary action to stir the metal and disperse fine argon bubbles through the melt. These bubbles are highly effective at catching any inclusions and bi-films, floating them to the melt surface, where they are trapped in the slag layer. The rotary action also homogenises melt temperature and eliminates cold spots. This allows the steel to be poured at lower temperatures, reducing shrinkage and promoting finer microstructures. This is all possible in a standard bottom pour ladle.

SEMCO FF water-based coatings reducing formaldehyde emissions

SEMCO FF coatings do not use biocides that release formaldehyde, especially within the coating drying process, when emissions are most concentrated. They therefore support foundries in complying with the new regulations and avoid the need for costlier and more complicated investments in new or upgraded gas treatment systems.

SEMCO FD waterbased fast dry coating

SEMCO FD is a range of water-based coatings designed for flow coating applications that will dry quicker than traditional water-based products. The range includes products with a variety of refractory fillers making them suitable for different metal types and casting conditions.

FEEDEX FEF fluoride emission free, highly exothermic and high pressure-resistant feeder sleeve

Foseco’s FEEDEX FEF sleeve range delivers fluoride emission free performance boost to high-pressure greensand iron casting.

FEEDEX NF1 exothermic feeder sleeves for non ferrous applications

FEEDEX NF1 sleeves from Foseco eliminate the need for exothermic riser powders. With the new FEEDEX NF1 range of exothermic feeders for aluminium, the application of exothermic powders to boost the feeding effect in the riser is unnecessary.

HOLLOTEX Shroud turbulence control and filtration for large steel castings

HOLLOTEX Shroud is a new process that can be effectively applied in steel foundries. A shroud is positioned in the mould, the bottom of the shroud protrudes into a filter box located at the base of the mould. When the ladle is in position, the shroud is mechanically lifted so there is a seal between the nozzle and the shroud. The metal flows from the nozzle, through the shroud into the filter box, and then to the runner. As the metal flows it is protected from exposure to air, eliminating the potential for air aspiration.

Reclamation of inorganic bonded sand systems

An increasing number of automotive aluminum foundries are replacing organic with inorganic binder systems in order to reduce emissions of volatile organic compounds and ensure a more sustainable production process. If an efficient sand reclamation process for inorganic-bonded sand were developed, it would provide further benefits in terms of reduced emissions and energy consumption. This study presents an innovative process for reclaiming inorganic-bonded foundry sand, based on a mechanically-adsorptive process known as the CLUSTREG process.

The Sustainability Advantage

Sustainability is a defining theme of the modern industrial landscape, particularly in energy-intensive industries, such as ferrous and aluminium foundries. Although often associated with increased regulation and costs, a strong positive business case can be made for adopting more sustainable technologies and practices, particularly as they impact energy and resource consumption. In two white papers, one for iron and steel and one for aluminium foundries, we discuss solutions currently available to foundries, which underline the advantages that sustainable business choices can bring to financial, environmental and social performance indicators.