Walking the talk, together: interview with Bradken

17 Jun 2023

There’s no doubt that the foundry sector is going through some testing times at the moment. Skills shortages. Rising quality expectations. Cost pressures. Decarbonisation… these were just some of the common concerns many visitors raised at GIFA 2023. And while specific solutions abounded on the stands of exhibitors, for one Australian foundry operator, the true value of the tradeshow lay in the potential for strategic partnership.

Bradken is a global producer and supplier of wear-resistant products, primarily mill liners and crawler systems for the mining and minerals processing industry. Founded in 1922, the company has grown over the past century and now operates a global network of foundries with locations in Australia, Canada, China, India, Malaysia, and the US. These cast a range of alloys, including nickel-chromium-molybdenum and chromium-molybdenum irons, white iron, manganese steel, and mild steels.

“We pride ourselves on our customer-centric approach, working with our customers to deliver solutions that meet their needs,” explained Stephen Hall, Global Head of Procurement at Bradken, speaking at the Foseco stand at GIFA. “At the same time, we have a desire to work with suppliers who embody the same values as us.”

The quest for partnership

It is this search for partners that brought Hall and his team to Düsseldorf and the largest global gathering for the foundry industry. “Here at GIFA, we are focused on building strategic partnerships with suppliers that have a global footprint and can provide global solutions to address the key issues facing us today,” said Hall. “This means looking at raw materials, equipment, consumables, and processes that deliver a total cost of ownership (TCO) benefit in terms of cost, quality, and sustainability.”

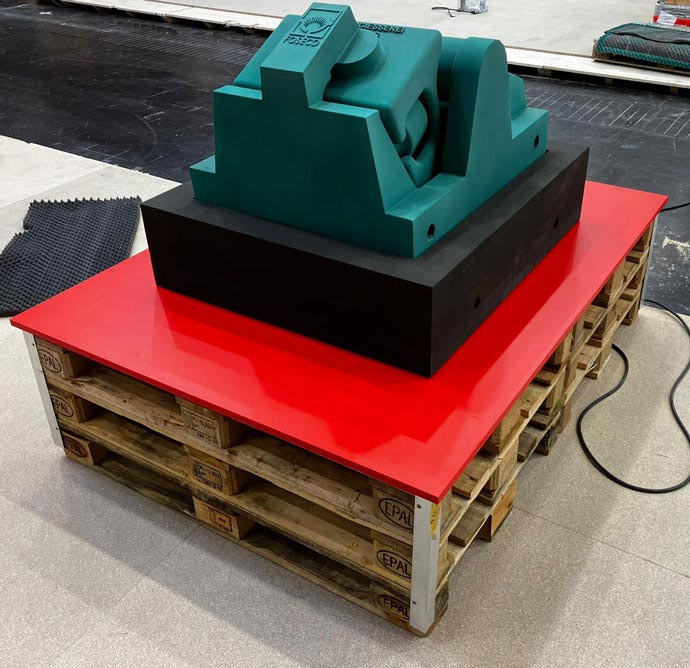

The ultimate aim is to work “more closely with fewer suppliers to deliver the solutions we need,” Hall continued, noting the company currently had more than a hundred suppliers to its sites around the world. Foseco – with its focus on innovation, partnership, and sustainability, as well as its global network of manufacturing facilities – was very much in view. “We’ve had some really constructive conversations here at the Foseco stand at GIFA, and I think there’s a really good opportunity for us to work together on a global stage.”

Partnership was not just on the Bradken team’s mind; it was also one of the key themes of the Foseco stand. “To navigate a way forward, we believe a collaborative approach is needed, with suppliers and foundries working together to find tailored solutions” said Rob Welland, Vice President of Marketing & Technology at Foseco. “It’s great to find a like-minded partner, such as Bradken, and we’re excited about the possibilities for future co-operation on a global scale.”

The sustainability question

Sustainability is one of those issues where partnerships will be key to delivering successful progress. “Bradken’s goal is become carbon neutral by 2030,” explained Hall. “We’re already on the way to achieving this. For example, we have made good progress in sourcing renewable energy contracts for our foundries, with some of our sites now achieving north of 80% sustainable energy. We are now looking at equipment and consumables suppliers and how they can help us meet our net-zero ambition. This been one of the most positive aspects here at GIFA, with many suppliers highlighting their own drive for sustainability.”

Bradken’s sustainability journey aligns with that of Foseco and its parent company, Vesuvius. Sustainability was another of the company’s key themes at GIFA, and its stand was included on the ecoMetals Trail. Organised by trade organisers, Messe Düsseldorf, this highlighted exhibitors that invest in innovative, sustainable, and economically-competitive technologies. Sustainability is also built into Foseco’s approach to business through its strategic sustainability goals. One of these is specifically to help customers reduce their CO2 emissions with products that reduce energy and materials consumption, improve yield and productivity, and reduce scrappage and re-work.

The Foseco stand itself also embodied the company’s attitude to sustainability, being paperless and using recyclable construction materials, when possible. This left a positive impression with Hall. “It’s good to see that, even at this level, when it comes to sustainability, Foseco don’t just talk about it; they’re doing it. This focus and attention to detail is the mark of company that we could do business with.”

Talk to us about how we can help you to shape the future and meet and exceed your needs for today and tomorrow. Do you have a challenge or problem for the future that you’ve been putting off tackling, because it feels too hard?