20 years of alliance for the benefit of our mutual customers

01 Jun 2023

Partnership past, partnership future: an interview with Dr Marc Schneider, MAGMA

GIFA is a tradeshow that brings the foundry world together. Thousands attend to make new connections and renew old acquaintances. But for two old friends in particular, this year’s event held special relevance, marking the 20th anniversary of their strategic alliance.

Foseco, a global supplier of casting consumables, and MAGMA, a leader in casting process simulation and virtual optimisation, officially joined forces to support their mutual customers in 2003. But as MAGMA CEO and President, Dr Marc Schneider explained in an interview at the Foseco stand at GIFA 2023, the relationship goes back about a decade before that.

Building a successful, decades-long relationship

“Foseco has been using MAGMASOFT®, our casting simulation program, for almost 30 years,” said Dr Schneider. “But in the early 2000s, we started to talk about intensifying that relationship. At that time, Foseco were looking for a tool that could be used by its application teams to visualize and characterise the performance of its products to its foundry customers, especially on the feeding and filtration side. For our part, it was an opportunity to dramatically increase exposure and highlight the uses and benefits of simulation software to much wider audience.”

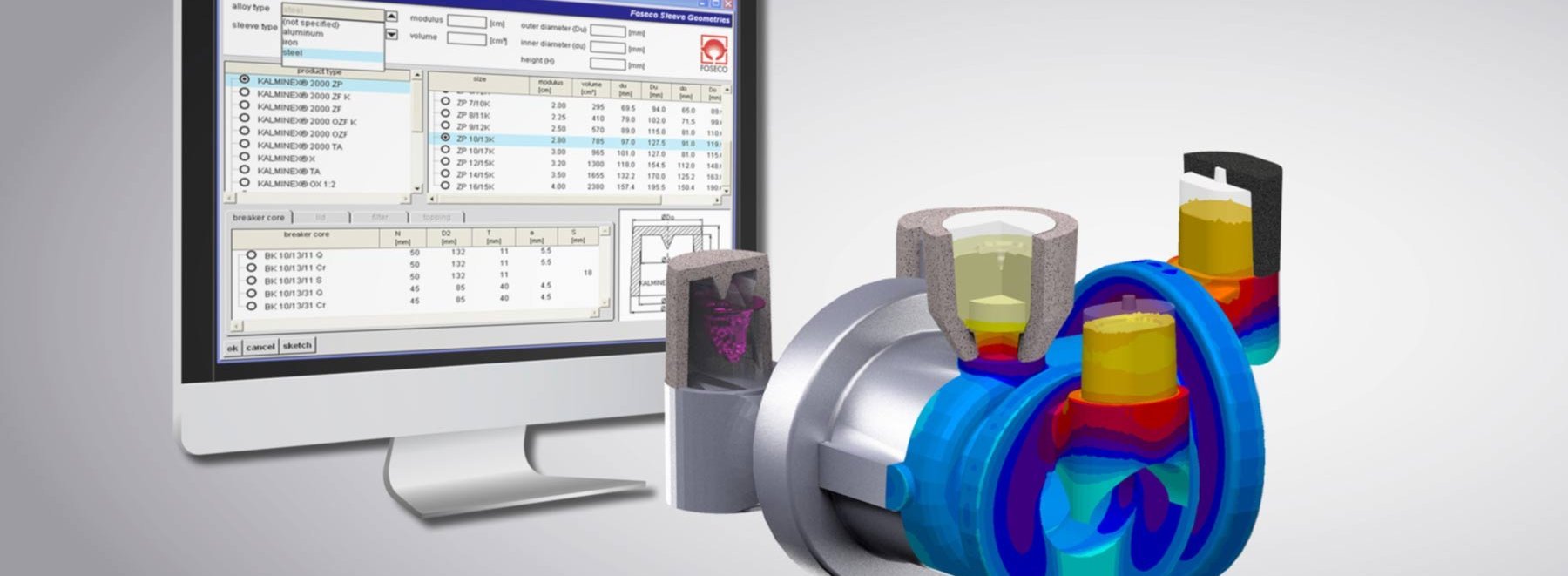

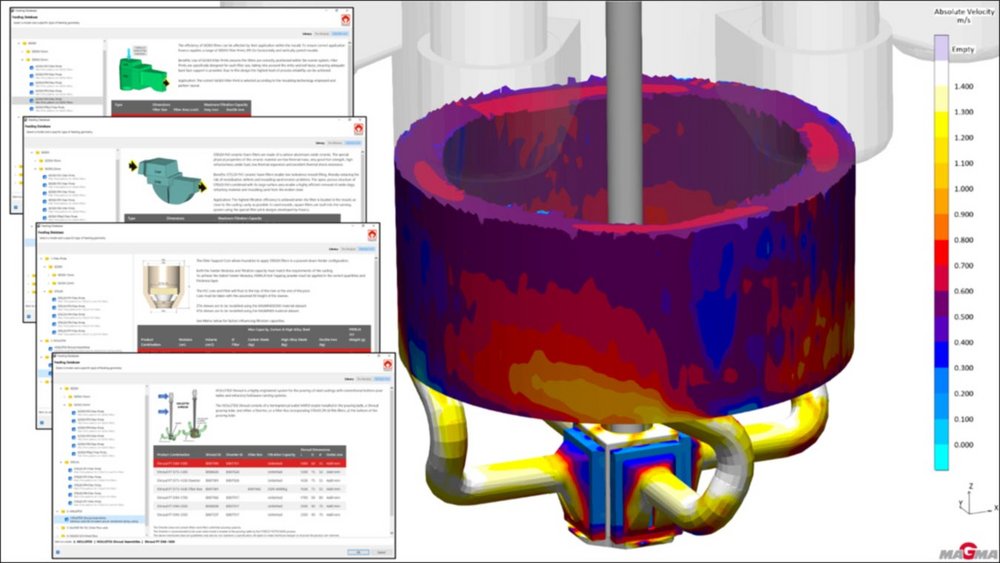

The strategic alliance was sealed in 2003. Under the agreement, MAGMA developed a special version of MAGMASOFT – MAGMASOFT Express – for Foseco engineers, allowing quick and efficient set-up of simulations, even in the field. The companies also jointly developed the first FOSECO Pro module for MAGMASOFT. Comprising a database of the main Foseco feeding and filtration products, with 3D geometries and their performance in casting, FOSECO Pro was the first available solution to describe the performance of foundry consumables based on first principles. It allows the user to quantitatively consider Foseco products in their simulation analyses.

“These products have continued to evolve over time as a result of many technical discussions between ourselves and Foseco,” continued Dr Schneider. “For example, we continually add functionality and new Foseco product developments into FOSECO Pro. The latest release includes Foseco’s shroud technology, as well as allowing recommended filter prints to be integrated into MAGMASOFT®. This has helped both our own ongoing development of the MAGMASOFT® software, but also aided product development on the Foseco side, for feeding systems, filters, and other applications of the company’s products.”

Benefits beyond the alliance

Both sides have thus benefitted over the last twenty years. “It’s been truly a two-way relationship. That was the idea when we started and, from my point of view, that has come to fruition,” said Dr Schneider. But the benefits are also felt far beyond the two alliance partners.

“Our simulation software gives foundries a common language with Foseco to discuss the application and performance of Foseco products within their specific foundry environment,” Dr Schneider explained. “It therefore facilitates dialogue and enables the collaborative development of solutions. It also allows foundries to efficiently characterise the performance of Foseco products when laying out castings in their engineering department. From this point of view, hopefully we have allowed our common customers to apply Foseco technology to the best extent possible in optimising quality and minimising resource consumption.”

The alliance has also helped to demonstrate more widely through the industry the value of simulation as an effective tool for improving day-to-day foundry practice. “Over the last twenty years, we have seen casting process simulation and virtual optimisation become increasingly accepted by and integrated into foundry applications, as its usefulness has both been proven and expanded alongside advances in the technology,” said Dr Schneider. “It is now an important part of many modern foundry operations, and I don’t think that will change in the future in light of the increasingly complex challenges faced by foundries today.”

A model for the future

Looking back at twenty years of partnership – and with the bustle of the GIFA crowd around – Dr Schneider also reflected on the importance of collaboration for solving those complex challenges.

“I’m sure the industry won’t get by without strong partnerships,” the MAGMA CEO concluded. “I think that has always been the case, but it will be even more so in the future. In that respect, the Foseco-MAGMA alliance can be regarded as a kind of “role model.” We have to use our own individual competencies and synergise them with others to come up with new products, new ideas, and new technologies, which allow the industry and its individual participants to succeed. I’m convinced that’s the only way forward.”

What does the future hold?

Many of these ideas were on display at the Foseco stand at GIFA, which was designed around three key themes: sustainability, innovation and technology, and partnership and knowledge. “This is the single best opportunity for us to engage with our customers on these different topics,” noted Laugier-Werth. “We have the right people here to have the right conversations. It is thus the ideal place to discuss ideas and solutions to the macro challenges we all face.”

And when it comes to looking ahead? Laugier-Werth is succinct: “It’s a simple vision of an industry enabled to deliver better quality products, cheaply, and with zero accidents and carbon emissions. That’s the industry we are working toward at Foseco; and it’s an industry I’m excited to help build.”

About MAGMA

MAGMA is a worldwide leader in developing and providing software for casting process simulation and virtual optimization. MAGMA stands for robust, innovative cast solutions and for reliable partnerships with the metal casting industry, including casting designers and buyers. MAGMA’s products unite the complexity of the casting process with user-friendliness to create economical solutions for its customers. MAGMA partners with its customers in the integration and effective use of the software, helping them to realize clear cost advantages. MAGMA’s range of products and services includes the simulation software MAGMASOFT® autonomous engineering, for virtual designs of experiments and autonomous optimization of casting processes, as well as comprehensive engineering services for casting design and process optimization.

Press Release "20 years of alliance for the benefit of our mutual customers"

Foseco and MAGMA, a world leader in casting process simulation and virtual optimization, celebrate the 20th anniversary of their strategic alliance with the release of a new version of the FOSECO Pro module.