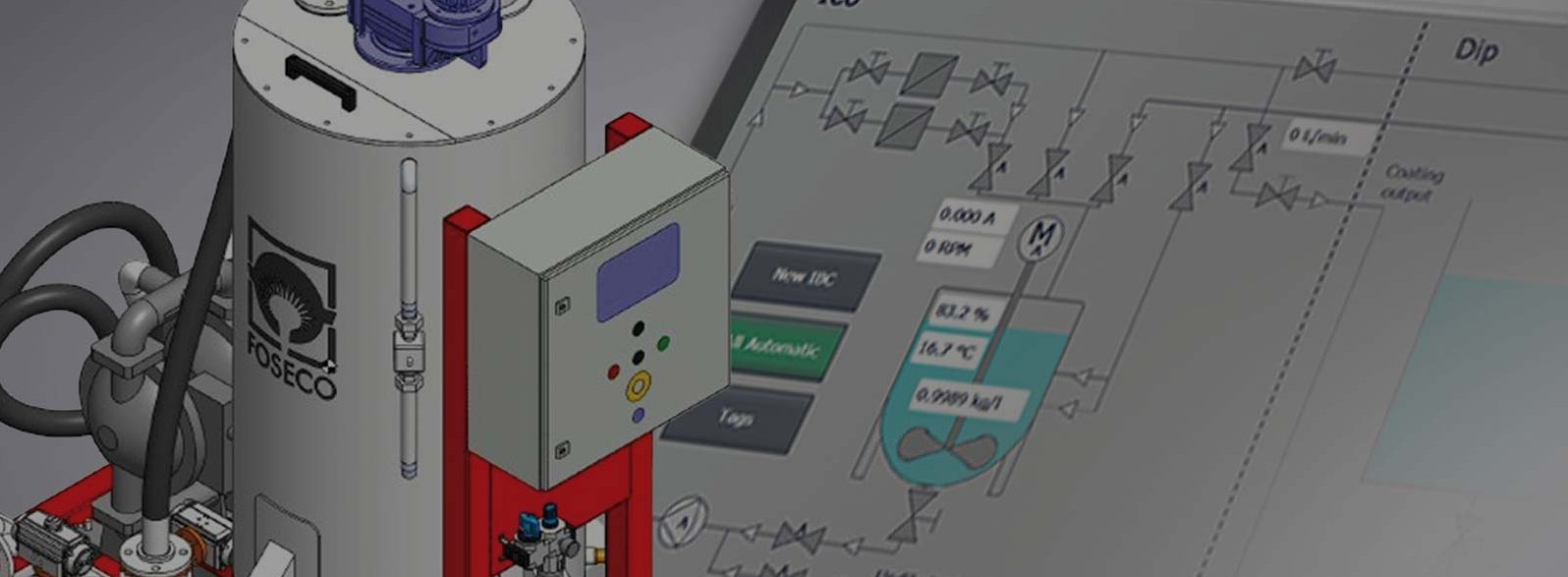

ICU

Intelligent Coating Unit (ICU) automated coating control and adjustment

- Reduced scrap and re-work costs

- Continuous measurement and control

- Automatic adjustment of coating

- Consistency of application

- Audit trail

Automated coating control

Increasing requirements from foundry applications such as thinner wall sections, complex internal geometries and new alloys, are driving the demand for high-performance coatings. However, high performance coatings need to be applied consistently to achieve best possible results on a repeatable basis.

Poor application control can undermine coating performance and can in some instances lead to excessive scrap or rectification work. Hence Foseco has developed a new range of equipment that is designed to optimise coating application.

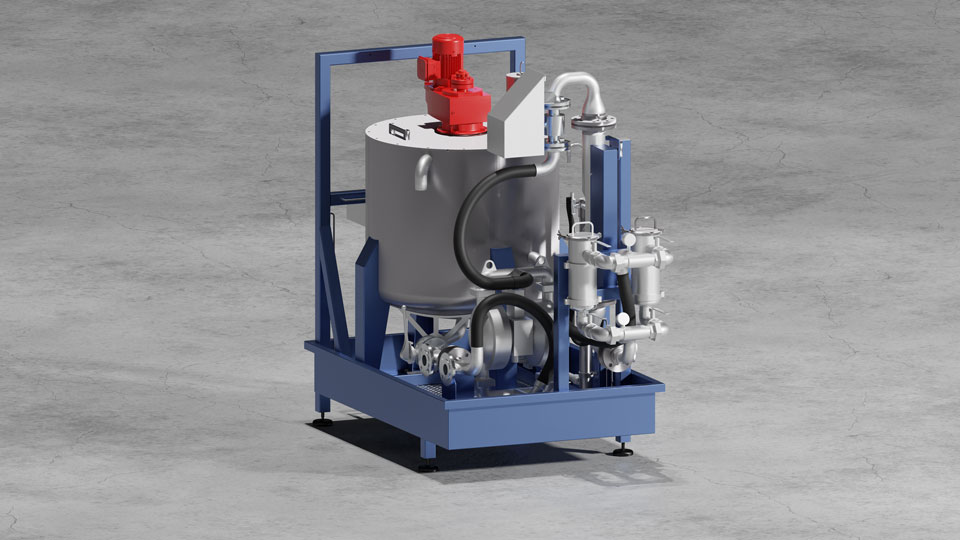

The product range

- ICU-Pro: the ‘mother’ unit on which all subsequent ICU units are based

- Integrated ICU: integratable with customer dip tanks

- Modular ICU: a lower-cost solution for foundries with limited space or that want a tailored solution

- Continuous ICU: to serve multiple end users without the need for a buffer tank

'The ICU is suitable for all application methods, including spraying, dipping and flow coating and can be connected to all major packaging systems, from drums to bulk silos.'

Contact

Christoph Genzler

Product Manager, Mould & Core