Improving sampling techniques for Vmet analysis of aluminium

02 Oct 2023

Melt cleanliness analysis is only as good as the sample analysed. In a new study, researchers at Foseco have demonstrated the benefits of two alternative sampling methods over traditional K-mold sampling for Vmet analysis of aluminium melt quality.

Why it’s important to understand melt cleanliness

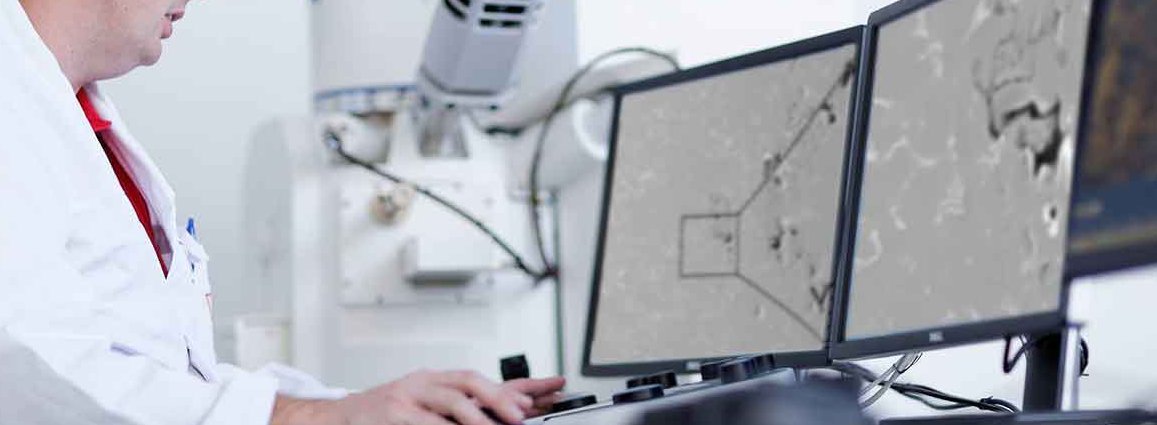

Vmet analysis enables foundries to precisely analyse the cleanliness of an aluminium melt. The technique involves subjecting a solidified aluminium sample to energy-dispersive x-ray spectroscopy (EDXS) in a scanning electron microscope (SEM). SEM coupled with EDXS records the size, morphology and composition of defects in the sample, according to pre-defined rules and image process algorithms that are specially adjusted for aluminium.

Understanding melt cleanliness through Vmet analysis therefore allows foundries to assess the effectiveness of melt treatment processes for improving melt quality, and to make adjustments to ensure appropriate standards are met. This is particularly important in the growing market for high-quality aluminium parts, notably within the automotive industry, where end-user specifications are becoming even more strict.

In this context, any improvement to the accuracy of the Vmet process offers the opportunity to gain even tighter control of melt cleanliness. Recent research by Foseco focuses on the sampling technique used in Vmet analysis to determine whether novel sampling techniques offer benefits over the traditional K-mold process.

Sampling techniques for Vmet analysis: the options

Vmet analysis enables foundries to precisely analyse the cleanliness of an aluminium melt. The technique involves subjecting a solidified aluminium sample to energy-dispersive x-ray spectroscopy (EDXS) in a scanning electron microscope (SEM). SEM coupled with EDXS records the size, morphology and composition of defects in the sample, according to pre-defined rules and image process algorithms that are specially adjusted for aluminium.

Understanding melt cleanliness through Vmet analysis therefore allows foundries to assess the effectiveness of melt treatment processes for improving melt quality, and to make adjustments to ensure appropriate standards are met. This is particularly important in the growing market for high-quality aluminium parts, notably within the automotive industry, where end-user specifications are becoming even more strict.

In this context, any improvement to the accuracy of the Vmet process offers the opportunity to gain even tighter control of melt cleanliness. Recent research by Foseco focuses on the sampling technique used in Vmet analysis to determine whether novel sampling techniques offer benefits over the traditional K-mold process.

New sampling methods offers improvements on K-mold process

The study compared the three sampling methods over a series of three trials in various conditions. Both copper mould and immersion sampling were found to result in samples with significantly lower inclusions than the traditional K-mold technique.

Combined with Vmet melt cleanliness analysis, these methods offer a more precise picture of melt quality at the micrometre scale, and therefore provide foundries the potential to more precisely control melt treatment to ensure the best-possible end castings. They also confirm the viability of the Vmet process for detailed and accurate assessment of aluminium melt cleanliness.

A comparison of different sampling techniques for aluminium metal cleanliness investigations

For a detailed discussion of the study and its results, check out the recent article 'A comparison of different sampling techniques for aluminium metal cleanliness investigations' by Dr Mert Kurttepeli, Head of R&D Services at Foseco Nederland.

Non-metallic inclusions in ductile cast iron, steel and aluminium castings

You can also read more about aluminium melt cleanliness in the technical paper 'Non-metallic inclusions in ductile cast iron, steel and aluminium castings' from Dr Wolfram Stets, Foseco International Technology Manager Metal Treatment, including types, causes, and detection of inclusions, and how to prevent them.