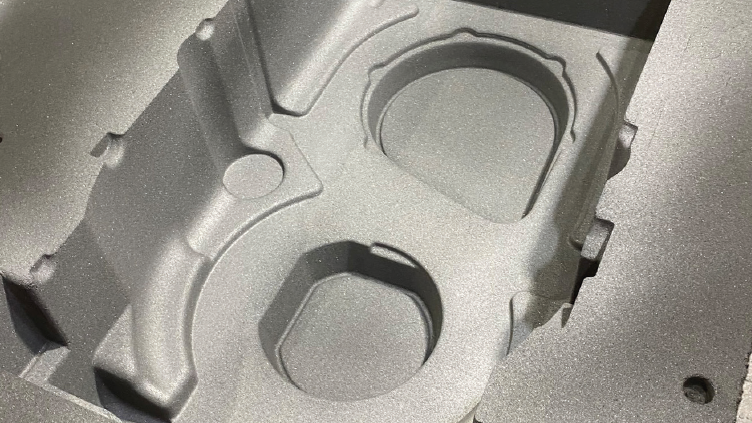

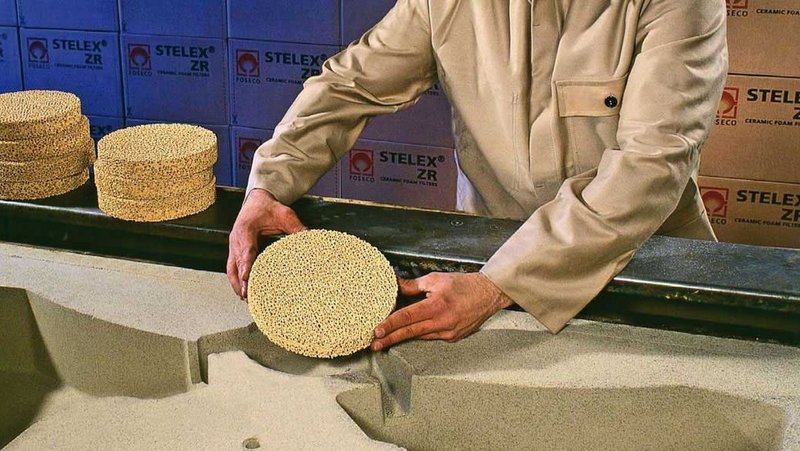

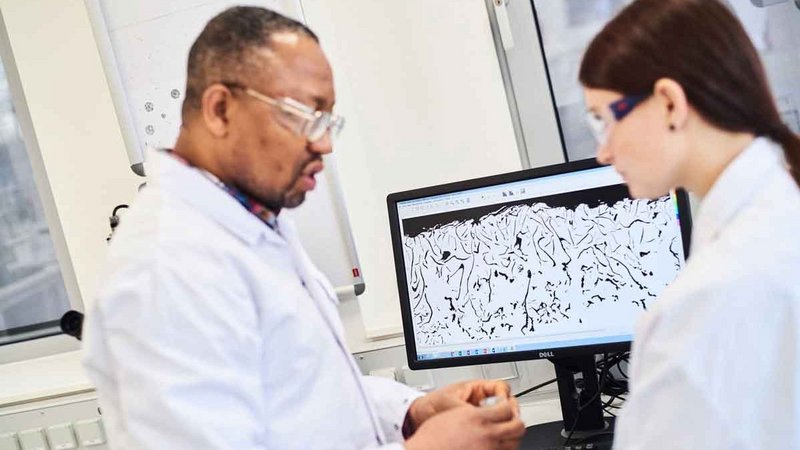

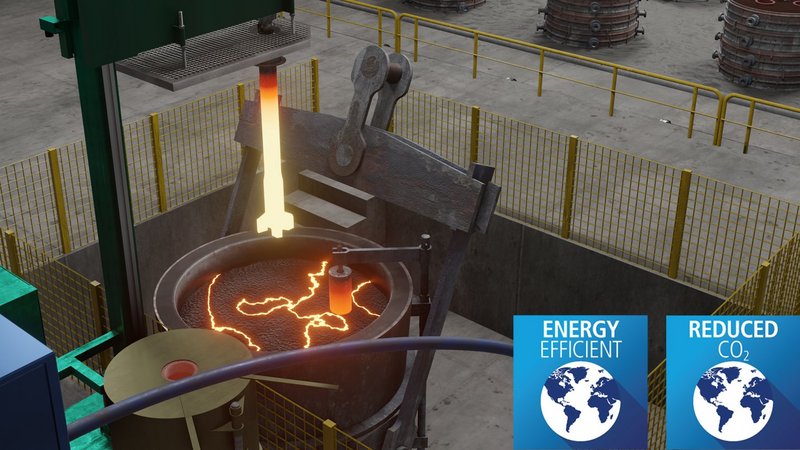

The causes of casting defects are numerous and can be found at most stages of the casting process - from the furnace to the mould. Casting defects significantly affect the efficiency, profitability and environmental performance of foundries. Our solutions and advanced computer simulation techniques allow foundries to reduce casting defects such as pinholes, shrinkage cavity, inclusions, scabbing, penetration or veining. Hence the Foseco products reduce labour-intensive fettling and machining, minimise metal usage requirements, influence the metal solidification process and automate moulding and casting, thus reducing cost, energy usage and mould size.

Our aim is to enable improved foundry performance by working alongside our customers to develop and apply products and services that produce better casting quality and higher productivity at lower costs in a safe and healthy working environment.

Products and solutions for improving foundry performance